A Circular Approach

The earth operates a closed system when it comes to resources, and an open system when it comes to energy production, which is why we approach everything we produce and consume in the full knowledge that it is here to stay.

Our industry produces a large amount of waste during the product life cycle, from design through to the post-consumer phase. A large amount of this waste is generated during the production phase. Post-consumer waste is also to blame. A total of 156,943 tonnes of post-consumer textile waste was generated in Italy in 2019, that’s almost three times as much as in 2010 (Italia del riciclo 2021).

Our commitment to circular fashion

At OVS, we’re challenging ourselves to embrace a new production and consumption concept, moving from a linear input-output model, it’s simply no longer sustainable seeing as the population is expected to reach 8.6 billion by 2030, resulting in an estimated 63% increase in clothing production. to a circular one, in which every element is regenerated and given a new lease of life.

Adopting a circular approach to design

In 2020, OVS launched Eco Valore, a set of three indicators that consumers can use to gauge the impact of their consumer habits. Among these is a product circularity indicator, which expresses how compatible a garment is with current end-of-life recycling processes on a scale of 1 to 10. During 2021, OVS refined its calculation methodology in collaboration with the University of Padua.

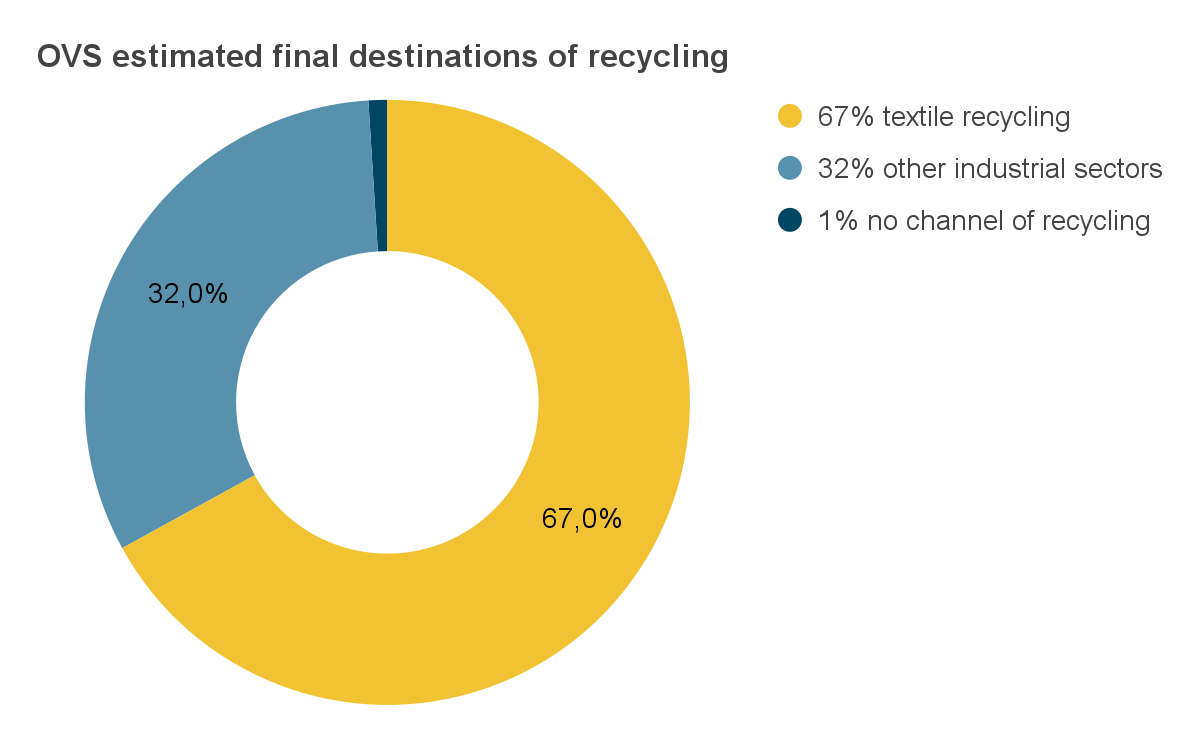

According to our circularity indicator, 67% of our garments can be recycled at the end of their useful life. This is because they are made from one material or a blend of materials that can be processed by the main mechanical and/or chemical-textile recycling channels.

On the other hand, 32% of our clothes can be recycled and used for other industries and only 1% has no way of being usefully recycled.

These statistics show that the industrial sector is simply not mature enough to recycle post-consumer waste generated by the fashion industry, and lacks organised waste collection systems. It also comes down to poor consumer awareness around the possibility of re-using garments at the end of their life.

In addition, we have also set ourselves the goal of using more recycled fibres so that we can give real weight to the concept of re-using clothing that has come to the end of its life. We are ready to experiment with innovative technologies that make use of processing scraps.

In the 2021 collections we produced over 1.800.000 items made from recycled materials.

Reusing production scraps

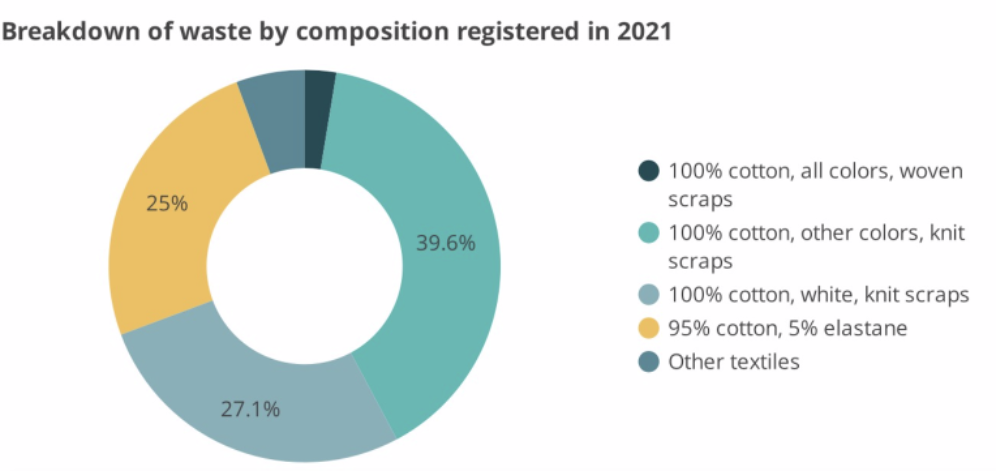

No matter how efficient it may be, the garment production phase always generates waste. We estimate that we produce around 10,000 tonnes of post-production waste when manufacturing our clothes (Higg Analytics).

This presents us with a great opportunity to reuse scrap materials that would otherwise negatively affect the environment.

Having achieved significant results in the Circular Fashion System Commitment 2020, OVS will continue its collaboration with the Global Fashion Agenda in a new strategic initiative.

A new global international partnership with one main aim: to accelerate the transition to a circular system that restores and regenerates materials, offering new opportunities for innovative design, greater customer engagement and the creation of shared economic value.

OVS is a member of the Circular Fashion Partnership (CFP), which is establishing a new brand-manufacturer alliance in Bangladesh in collaboration with BGMEA (Bangladesh Garment Manufacturers and Exporters Association). The scheme intends to make production scraps into recycled yarn, which will be used to produce new garments. The idea is essentially to create a circular, traceable production system, with the hope of extending the scheme to other countries.

In this way the production scraps will provide the raw materials for the creation of new collections, thus avoiding the dispersal of thousands of tonnes of unused fabric in the environment and reducing the impact of the production of new materials.

CFP is an opportunity to lay the foundations for the large-scale local recycling of post-industrial textile waste in manufacturing countries.

Making use of unsold goods inventories

In keeping with the objective of not losing the value of items at the end of their life, we have a strategy for minimizing inventory that, once the possibility of using commercial channels to sell the stock has been exhausted, allows OVS to use philanthropic channels such as the donation of garments to people in need or in response to international emergency situations.

OVS has a profound awareness of its impact in terms of sustainability, but this does not mean that environmental protection should be pursued at all costs, when consumer protection is at risk. Therefore, when no other inventory recovery channel can be used because the remaining stock has irreparable defects that make it unmarketable, it is recycled by specialised partners or disposed of through industry specialists.

In the period 2018-2019, a total of just 138,687 items were sent to the shredder, while in 2020 and in 2021 there was no waste at all, while in 2022 there were 36.443 items sent to the shredder.

Over the years we have also perfected a scheme for reconditioning and distributing unsold goods, which minimises the quantity of clothes we have to send to the off-price channel or to be scrapped. Both in 2021 and 2022, more than 11 million garments were reconditioned and redistributed to points of sale.

Production samples are also recovered through donations to local charities or through internal sales reserved to staff, 164.978 items in 2022.

2022 Preconsumer breakdown

| CHARITY | 164.978 items |

| STOCK | 7.023.367 items |

| SHREDDER | 36.443 items |

| REFURBISHED | 10.852.548 items |

| TOTAL UNSOLD | 18.077.336 items |

GIVING GARMENTS A SECOND CHANCE

Furthermore, we are aware that one way to minimise the waste of resources is to offer our customers a durable product and with it the means to make it so.

On the OVS e-commerce website customers can find tips on how take care of their garments and extend their life. Also, in 7 stores, among the most important, there is a tailoring and repair service and garments with parts more susceptible to wear and tear are now sold with replacements to facilitate minor repairs.

In 2022 OVS launched an investment project involving the creation of a technological innovation hub in Puglia (in the south of Italy). A multifunction center with a view to sustainability and circular economy, with a reconditioning plant to extend the life of the garments,and a plant to make tests of the recycling of fibers.

Moreover, last year OVS in order to probe the consumer’s predisposition towards the practice to support the clothing longevity and slow down consumption of the new clothing, has launched two experimental initiatives:

- a test of a children's clothing rental platform on e-commerce

- the opening of a few second-hand clothing sales corners in selected OVS stores in Milan.

Collecting used clothes from consumers

In 2022, the initiative to collect used clothes, active since 2013, was relaunched with the "Dona i tuoi abiti usati a Humana" programme. Thanks to the partnership with Humana People to People Italia in the over 800 stores in the OVS sales network, customers can deliver used clothes by entrusting them to the international cooperation organization, thus avoiding accumulation in landfills.

The collected garments are analyzed - at the Humana logistics center in Pregnana Milanese - according to strict standards. 67.5% is intended for reuse, 25.5% is transformed into new fibers and 7% is used to produce new energy.

Environmental labelling for packaging

In compliance with Italian Legislative Decree 116/2020, OVS has started to produce environmental labels that state where end consumers can recycle their packaging. These labels feature a QR code, which consumers can scan to view a webpage containing detailed informations on how to dispose of their packaging.